Blackish-Blue Bruise Coloured Hydrogen Part 2:

The Ghost of Blue Hydrogen’s Future

As we found in Part 1, conventional hydrogen production from natural gas using steam methane reforming (SMR) coupled with carbon capture and storage (CCS) is easily written off as a waste of everyone’s time and money. It’s fooling nobody. Because nearly half the CO2 emissions come from combustion in the tube furnace and other combustion equipment, there’s no more benefit to going after high CO2 captures off this equipment than from fossil gas power plant flues or the like. We’d need something new such as SMR run with renewable electric heating to give SMR a shot at survival into a decarbonized future.

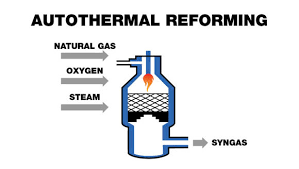

Undaunted, hydrogen-as-a-fuel advocates reach for another technology: autothermal reforming (ATR). ATR isn’t something new or unknown: it is a process used at very large scale today when high carbon monoxide (CO) to hydrogen syngas mixtures are required for processes like Fischer Tropsch or methanol synthesis.

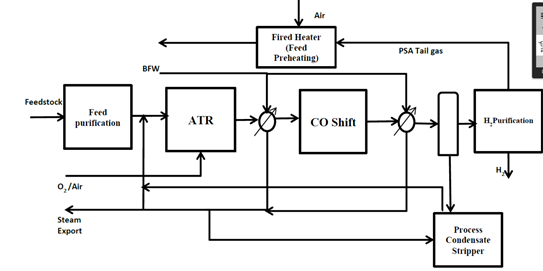

Autothermal reforming works the same way, in thermodynamics terms, that SMR works: you heat up a mixture of methane and steam to high temperatures and pass it over a catalyst, so that endothermic reactions can transform it into a mixture of CO and H2. But whereas SMRs combust fuel and transfer the heat through catalyst tubes in a tube furnace to the syngas mixture inside them, in an ATR pure oxygen is fed with the steam and methane feed in a special burner or partial oxidation catalyst inside a refractory lined pressure vessel. The heat is produced by in situ partial combustion, and the feed stream is massively overheated before being passed over the catalyst rather than supplying heat as the reactions proceed. The result is that some of the product hydrogen and CO are also combusted and hence wasted, but all the combustion products (CO2 and water) are contained in the syngas product and hence are easier to capture and remove. The downstream steps: heat recovery, water/gas shift reactor(s) and gas purification are otherwise identical to the SMR, with the exception that there’s now no fuel-hungry tube furnace to dump the gas purification system’s waste hydrogen into.

The process is, as already mentioned, less efficient than SMR if the target is pure hydrogen. Actual “efficiency” figures given are usually polluted with values being given to “export steam” that make comparisons challenging, but that ATR is less energy efficient at making H2 than SMR, assuming CO2 can be disposed of the good old way, to the atmosphere, is not in doubt. The process is currently optimized for the production of higher CO/H2 ratio syngas mixtures which are then blended with SMR output to produce the desired ratio for F-T, methanol or other syngas uses, because ATR can do that and SMR can’t without a risk of soot generation and other problems. Air-blown ATR is also used in a multi step reformer package to make H2/N2 mixtures as a feed for the Haber Bosch ammonia process.

Of course ATR is reached for by blue hydrogen advocates as soon as somebody realizes that the best possible capture from SMR, without major changes, is going to be about 50%- even ignoring methane emissions, due to SMR’s horrible burner box. So: how “blue” can we make an ATR?

If you a) take a few hits from the #hopium pipe, b) ignore methane emissions and c) restrain the project to using only renewable/nonemitting energy sources to run the CCS equipment, the answer is “as blue as you can afford!”.

In purely technical terms, there is no problem at all to remove 99.999% of the CO2 from the resulting hydrogen stream. If that were NOT possible, the product hydrogen would never meet fuelcell specifications which require the total of CO + CO2 to be below 10 ppm to avoid killing the fuelcell’s catalysts. Of course “removal” is just the first and easiest of the steps- you next need to capture, purify and store the CO2 away permanently.

Recall that the Shell Quest project targeted an 80% capture of the CO2 in the syngas mixture from the SMR, which it achieves, except when it doesn’t. That’s a fairly easy capture target from a stream with a high partial pressure of CO2 at a modest absolute pressure, and of course it’s only 80% of about 1/2 the CO2 emitted by the SMR. But as you increase the fraction of the CO2 you want to capture, two things increase: 1) energy use and 2) hydrogen wasting. The former is true in any capture process, arising from an increasingly fraught battle against entropy. While the thermodynamics and energetics are complex and vary greatly from flowsheet to flowsheet, to a first approximation, the energy to remove each order of magnitude of mass is about equal, i.e. 99% capture costs twice as much energy as 90%- for capture, not for capture and storage.

The hydrogen mass loss is likely the more challenging problem, and not just because of the need to throw away valuable product. Removing hydrogen from the captured CO2 would require yet more equipment, energy and flowsheet complexity. Unlike in the “good old days”, when hydrogen was treated as something you could vent without consequence, we now know that hydrogen itself is a GHG with GWP between 11 and 60x that of CO2. And whatever CO2 you don’t capture in your sequestration train, is going to come out in a swamp of H2 and other gases in the gas purification pressure swing absorption (PSA) unit. Without combustion equipment to easily use this material, and with the option to recompress and feed this stuff into the ATR feed being unpleasant for a number of reasons, it is likely that one would be tempted to just burn and vent the flue gas in some unabated combustion unit somewhere. That of course means you will have unabated CO2 emissions coming from that combustion stack.

The real killer to this idea however is those pesky initial assumptions we made when we were high on #hopium.

We might, because of foolish or ignorant regulation, be permitted to just ignore or discount the methane emissions, as is clearly the case with the Shell Quest project which doesn’t even mention them in its public reporting. Remember that methane emissions take Quest’s net CO2 capture from 35% to a real CO2e capture around 21%- from poor to positively craptastic. But the atmosphere won’t give us the luxury of accepting the design philosophy of Mediocrates, whose response to criticism is, “Meh- good enough!” Global warming potential (GWP) is GWP, whether it’s from CO2 or methane emissions. You can’t just pretend that methane doesn’t matter!

If you remember from Part 1, methane leakage at world average leakage rates of 1.5% add about 4 kg of CO2e for every kg of H2 produced, i.e. Methane leakage adds about 40% to the ~ 10 kg of actual CO2 released from an unabated SMR per kg it produces. So if you’re looking for CO2e capture (the total of CO2, methane, N2O and other GHGs from the process) to be very good, you basically would be forced to use the very best, lowest leakage fossil gas sources on earth, i.e. Norwegian gas, the gold standard as far as leakage goes, with leakage below 0.05%. My suggestion would be to forget about any blue hydrogen production from LNG, irrespective of its source- you need access to excellent gas via pipeline, because the leakage/venting from the extra steps to liquefy, transport and revapourize LNG will take you over the top.

Remember also that you need green electricity, and lots of it, to provide the capture and sequestration energy. ATR will generate the needed surplus heat as a result of its reduced efficiency relative to SMR, but you’ll need lots of green electricity- backed up with storage- to be able to run your ATR continuously (the only way hot units like this can run). You’ll need it to run the air separation plant, and the capture equipment, and the storage and CO2 transport compressors. Of course if you were a moron, you’d run this equipment off your product hydrogen, and watch your economics swirl down the toilet.

Finally, we can’t forget about carbon sequestration, i.e. storage. Remember that Shell Quest has an ideal storage reservoir only 60 km away from the plant, 2 km below ground. Because of the economics of CO2 sequestration, we’ll need to be nearby to a sequestration reservoir with capacity enough to take the effluent from our plant from its entire 30+ yrs of design life. And NO, we can’t accept enhanced oil recovery use for this CO2, because if we do, the atmosphere gets not only the CO2 released when that oil is burned, it gets about 40% of it back again when the oil comes to the surface. EOR is not CCS!

So: to make ATR capable of making truly blue hydrogen, any project has to line up just exactly right. It must have:

1) pipeline access to ultralow leakage fossil gas of adequate capacity

2) pipeline access to a nearby disposal reservoir of adequate capacity (forget about liquefying and shipping the CO2, that’s just going to break the bank and blow the CO2 emissions budget by time you’re done)

3) access to high capacity renewable electricity, backed up with storage to permit continuous operation (begging the question- why not just make green hydrogen!?!?!)

When I ran the numbers assuming 95% CO2 capture, 0.05% methane leakage, a world class ATR efficiency, and renewable electricity running the entire carbon capture and storage infrastructure, I was able to get the emissions down to about 1.2 kg of CO2e per kg of hydrogen produced- only about 20% more CO2e emissive than green hydrogen made by electrolysis using renewable electricity can already achieve today.

As to the cost of doing this, let’s just set that aside and dream the dream for a moment!

Hmm, are we seeing any ideal locations on earth yet? Which meet all these criteria, to make truly blue hydrogen?

Me neither.

Are we seeing enough of them to pump up the deflated dream of wasting hydrogen as a natural gas replacement fuel?

Nope.

I am however seeing lots of places which meet a couple of those criteria, who are hoping that nobody notices that the resulting hydrogen is still very blackish blue and bruise coloured, and hoping that a credulous government somewhere will turn a blind eye and write a blank cheque.

As to the notion of this kind of project being “transitional” while we wait for green hydrogen to get cheaper, please remember that this is nothing like bolting a CCS unit onto an existing SMR plant already feeding black hydrogen to a refinery or upgrader somewhere. We’re talking about bespoke new equipment, at scale so it’s cheap enough per kg, with a design life of at least 30 yrs. Equipment that doesn’t make economical hydrogen relative to today’s standard, but which is being done this way simply because it allows the energy of fossil gas to be made into fossil hydrogen with CO2e emissions that some government regulator somewhere finds tolerable. There’s no way anybody is going to build this stuff unless they’re guaranteed to be able to run it for at least those 30 yrs, unless somebody else is paying all the capital.

Finally, a reminder that even black hydrogen is not a cheap fuel. The ten year average for wholesale Henry Hub gas in the US gulf coast has been around $3.50/MMBTU over the past 10 yrs or so. Such gas can be made into saleable wholesale black hydrogen for about $1.50/kg- the aspirational target price for green hydrogen in, say, 2040 if you’ve had a few hits from the #hopium pipe, and 2050 or beyond (or never) if you’re skeptical like me. That hydrogen already costs $11/MMBTU. While I know full well that North Americans have access to incredibly cheap gas, and by world standards $11/MMBTU doesn’t sound like a very high price, I remind you that this is a wholesale cost and includes zero cost for storage or distribution. Those costs are going to be high, are going to be higher than for fossil gas for reasons of basic physics, and will be much higher than many imagine because the existing fossil gas infrastructure cannot be re-used for its distribution.

Personally I think that blue hydrogen should be taken off the barbeque because it’s been charred on all sides.

It’s done.

And while some governments are waking up to the same conclusion, as a result of the efforts of the @Hydrogen Science Coalition and numerous other groups, we can’t forget that blue hydrogen is of existential importance to the fossil fuel industry. Blue hydrogen is their “get out of jail” card in the energy Monopoly game. Even as a mere idea, rather than an actual technology, blue hydrogen allows fossil gas producers and distributors to pretend that they have a future in the energy supply market post decarbonization. They will not give up on this idea easily, and economics will drive them to put makeup over the bruises rather than making hydrogen truly blue, because the latter is very geographically limited and will also be very costly. It’s my hope that you won’t be fooled.

Disclaimer: everything you’ve just read was written by an ordinary human being, fallible and capable of error in the most mundane ways. If you find something that I’ve done wrong, and can provide references or calculations which demonstrate where I’ve gone wrong, I’ll be grateful and happy to correct my work.

If what I’ve written makes you angry merely because it puts your future ride on the fossil fuelled gravy train in doubt, then be sure to take it up with Spitfire Research.